Cutting-Edge Aerospace and Beyond Turned Components Quality Control

At APT Leicester, our dedication to customer excellence shines through in our consistent investments. The Keyence IM-7030T, an advanced image dimension measurement system, is a prime example. This tool enhances our CNC turning prowess and efficiency, reflecting our unwavering commitment to quality, underscored by our AS9100 Rev D Aerospace accreditation.

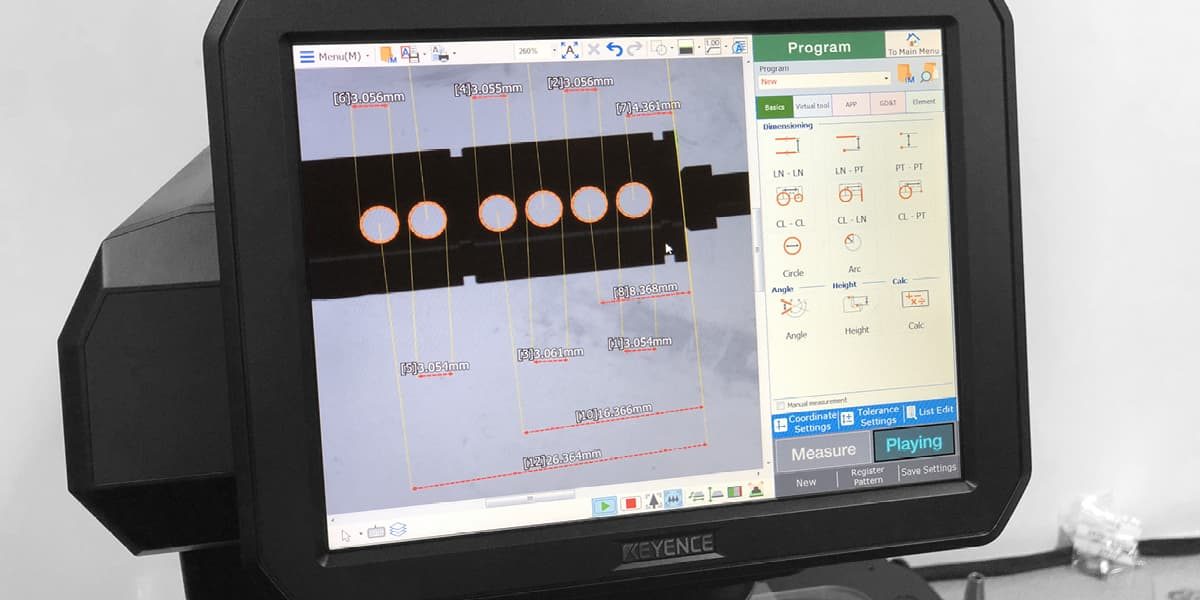

The IM-7000 Series revolutionises measurements of precision mill turned components, delivering accurate results irrespective of component shape or size. Having used the Keyence for over three years, we can attest to its unmatched efficiency in our daily operations. It can simultaneously measure features like width, height, and radius, a testament to the unit’s exceptional capability.

Imagine acquiring up to 99 measurements in mere seconds or inspecting up to 99 parts at once. This is precisely what this system brings to the table, drastically cutting down time and effort for CNC machining inspection. The user-friendly interface ensures all our trained staff can harness the full power of this advanced technology. Automated features such as positioning, orientation, focus adjustments, and edge detection make the Keyence IM-7030T a game-changer in our sector.

Its innovative ring illumination coupled with the light probe unit achieves measurements with unprecedented speed and accuracy. Designed thoughtfully, the probe’s deep-set shape and rounded edges ensure there’s no need to pre-filter or worry about deforming soft turned components during measurement. As a result, inspection times plummet while maintaining impeccable quality standards.

Training our team on this state-of-the-art system has augmented our inspection throughput. This efficiency means that our measuring equipment is frequently available, thereby boosting our overall output. Customers are the ultimate beneficiaries, enjoying expedited production and delivery timelines, with the consistent, high-quality standards they’ve come to expect from APT Leicester.

Our reputation for unmatched expertise and top-tier component quality is well-established. Holding AS9100 Rev D and ISO 9001 accreditations, we set the bar high for precision turned parts and CNC milled components. Rigorous assessment and monitoring of our manufacturing processes ensure we consistently exceed these high standards. We also offer all complete traceability and tracking throughout the production journey of each turned component for added peace of mind.

While we’re a leading UK subcontractor for the Aerospace sector, crafting precision turned components using especially lightweight aerospace aluminium, our capabilities extend far beyond. We’ve been pivotal in the Security industry, producing cutting-edge Euro cylinder lock body on our fixed head lathes and various other brass and stainless steel lock components for diverse applications.

The addition of the IM-7030T elevates our ability to surpass our own stringent manufacturing standards. At APT Leicester, our commitment isn’t just to deliver quality but to do so efficiently. With the backing of our AS9100 Aerospace accreditation, customers can be assured of the specification adherence of their orders.

We understand that value, paired with unmatched expertise and skill, is vital in producing and assembling components. If you seek this blend of quality and efficiency, reach out for a CNC turning quote. Give APT Leicester a call on 0116 287 0051 or send us an email with details of your requirements.