CNC Machining Service

APT Leicester offers comprehensive solutions for heat and surface treatment for finished parts. With our trusted local partners, we enhance the performance and longevity of CNC turned components. Our years of experience enable us to advise on the best finishes and heat treatments, ensuring improved performance for every part.

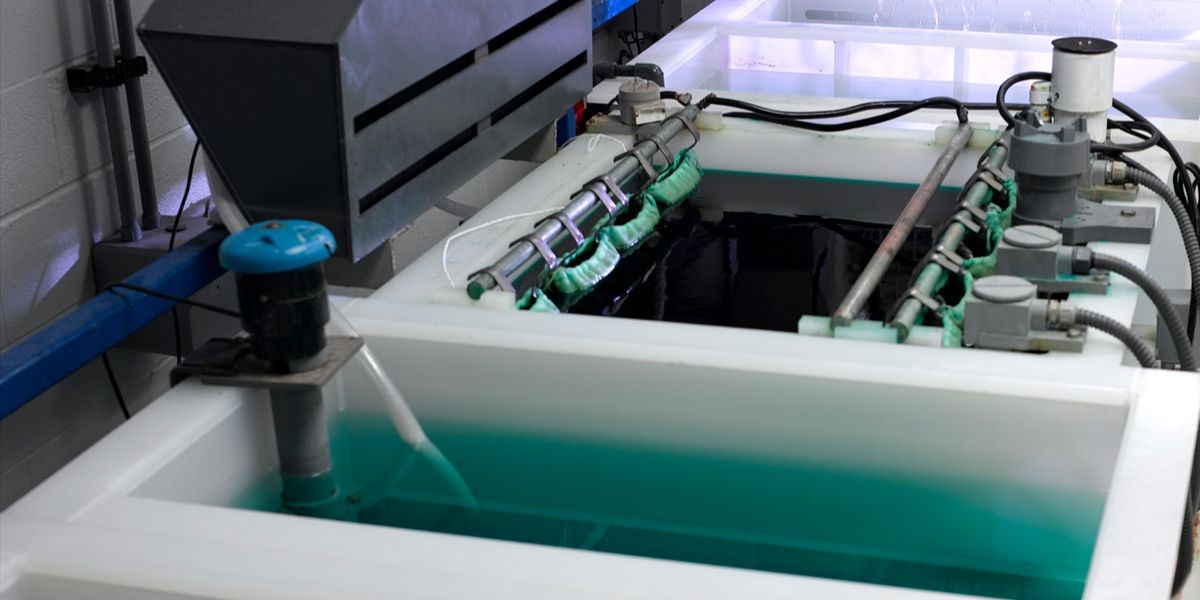

At the outset of our finishing process, every turned part undergoes a thorough cleaning using our advanced Mecwash MWX300 aqueous cleaning machine. This step is crucial as it combines ultrasonics with high-flow washing, ensuring that each component is free of contaminants and ready for further processing. This initial cleaning stage is fundamental in maintaining the high standards of quality APT Leicester is known for.

We recognise the importance of customised heat and surface treatment for CNC turned parts as specified by our customers. Offering a variety of options, we guide the selection of the most appropriate surface finish at the design stage, considering aspects like hardness, corrosion resistance, and solder-ability, to ensure the part meets the exact application requirements.

Each material used in CNC turning requires specific heat and surface treatments to enhance its properties and ensure optimal functionality. Here’s an overview of the treatments we offer for various materials such as mild steel, stainless steel, brass, and aluminium, each tailored to improve performance and durability.

Options for steel turned parts include case hardening for wear resistance, carbonitriding for surface hardness, and black oxide for corrosion resistance.

Treatments such as passivation to enhance corrosion resistance and electropolishing for a smooth finish are commonly used for stainless steel turned parts.

Many brass turned parts receive treatments such as passivation, chemical and chrome electroplating to enhance appearance and functionality. Sometimes clear coating is used to maintain colour and prevent tarnishing, boosting both aesthetics and longevity.

For aluminium turned parts, anodising is the preferred surface treatment, providing corrosion resistance and a decorative touch. This includes colour anodising, a choice for its aesthetic appeal, ensuring CNC machined components fulfill both functional and design specifications.

We offer on-site barrel polishing, shot blasting, and oiling, all undertaken in-house at APT. These services are available upon request to ensure your components receive the perfect finish, complementing our precision manufacturing, addressing specific customer needs and AS9100.

Look no further! APT Leicester incorporate specific allowances in production for heat and surface treatment changes, ensuring high-standard precision parts. We collaborate with trusted experts for quality outsourced finishes and rigorously inspect each product. Contact us for superior heat and surface treatment solutions to enhance your components.

“Great turned parts quality and service. We were kept informed throughout, it made a refreshing change for an order to run so smoothly. We would highly recommend this company.”