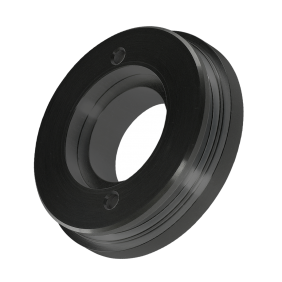

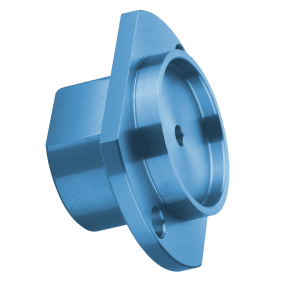

Turned Parts Assembly

APT specialises in the engineering of precision turned parts for a wide range of sectors. We’ll take your components from initial drawing to final design. We’ll then undertake the precision machining, heat treatments and surface finishing. Finally, your precision turned components will be assembled, packed and delivered to you in perfect condition.

Whatever you need, we can machine a wide array of materials, encompassing stainless steel, brass, plastics and titanium.

Our machines can turn parts from 0.5mm to 65mm in diameter from bar, nd we can handle billet work up to 300mm in diameter. This versatility gives us plenty of scope for creating small, intricate components and larger, complex assemblies.

For more detailed information, including insights into our turned parts and CNC milling processes, we invite you to visit our FAQs page, where we address our customers’ most frequently asked questions.

APT continually invests in the latest tooling equipment and CNC manufacturing methods, so our CNC workshop is set up for peak performance and productivity. This means you can rely on us for exceptional precision turned parts quality and a quick precision machining service turnaround on your order.

Our CNC lathes use the latest high performance lubricant program. This means they’re always operating at maximum capacity. The CNC workshop is also equipped for lights-out manufacturing, which allows us to work on your project 24/7.

For your peace of mind, all our fixed head and sliding head lathes can be monitored remotely for guaranteed excellence.

Our CNC workshop features an extensive range of Star Micronics sliding head lathes, Miyano and Doosan lathes, which have a fixed head (see list below). These are all bar-fed with driven tooling and high pressure coolant.

The spindles run at up to 15,000 rpm, which lengthens the tool life and enhances the quality of your precision turned parts surface finish. These CNC lathes are also fitted with sub spindles, which result in faster production or precision turned components and lower costs.

All CNC machines are covered by an ongoing tooling maintenance programme and are maintained by the Original Equipment Manufacturer (OEM).

Our precision machining service is a perfect complement to our CNC milling service.

Whatever your needs, we’ll be happy to discuss them with you and propose precision turned components solution, however difficult the precision machining may seem.

We always enjoy a challenge! Send us your precision turned parts requirement using the enquiry form below and we will get back to you with a precision milling quotation!

To ensure we can provide you with an accurate and timely quotation,

please provide the following details:

1. Drawing: Attach a detailed drawing(s) of the part if available.

2. Material Specification: Specify the material(s) required for the part.

3. Quantity Required: Indicate the quantity of parts required.

4. Additional Specification: Include any additional specifications such as ISO specification or customer-specific requirements.

5. Full Contact Details: Please provide your company’s full contact details.

6. Found Us Through: Let us know how you heard about APT Leicester. Your cooperation in providing this information will help us serve you better.

Thank you!

“APT’s turned parts knowledge was the best we had ever received. Their design team had solutions to problems that other engineering companies did not even think of. APT gives a complete package: service, quality and on time delivery.”