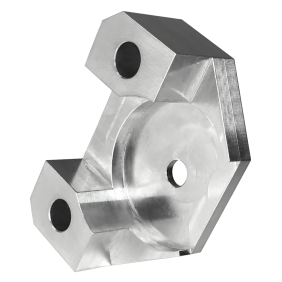

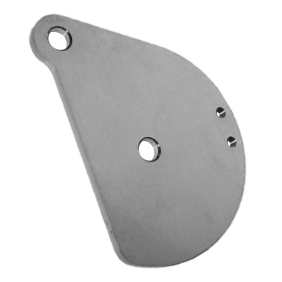

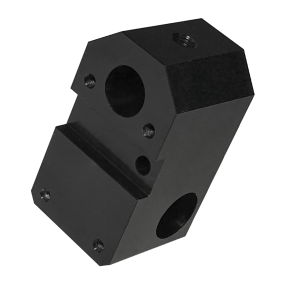

Precision Turned Parts

APT’s CNC workshop is equipped with Haas CNC milling centres, which are capable of precision machining high quality milled parts, at high capacity, for a quick turnaround. The Haas CNC machine centres are supported by a range of other machines, which take care of cleaning, polishing and quality control.

You need high quality milled parts, delivered quickly, so we’ve invested in the latest high capacity, multi-axis CNC machine centres. The technology has increased our production capacity by significantly reducing the chip to chip time.

Each machine has a bespoke pallet loading attachment, which loads the parts more efficiently for a quick turnaround. Each axis machine can be loaded with, and produce, up to 24 parts at once.

To give you the best possible price, we’re committed to keeping manufacturing costs down. Our Haas Super Speed VF-2 vertical machining centres are fitted with a high speed side tool changer. This optimises production times and reduces cycle times, which makes it more cost-effective.

Our Haas CNC machining centres have a 700mm x 400mm working area, operating with a 12,000rpm spindle. They can produce CNC milled parts up to 700mm long.

Visit our FAQs page for in-depth information and insights into our CNC machining and milling services, where we comprehensively address the most common queries from our customers regarding our CNC milling services and processes.

To offer you the very best service CNC machining services, we are continually improving our workshop and upgrading our CNC milling equipment. This has led to an investment in high capacity, multi-axis CNC machines.

Our Haas machining centres are equipped with the latest, ultra-fast multitool changers. This means you can have exceptional quality products, precision machined in the shortest possible time and a wide range of machining materials.

The machining centres are also equipped with the latest Renishaw probing systems. These allow the features of your CNC milled parts to be checked and verified during the CNC milling cycle. The result is a quick turnaround while maintaining the highest levels of quality control – to AS 9100 and ISO 9001 standards at all times.

Our vertical milling machines are a perfect complement to our CNC turning service.

Regardless of your specific needs, we’re ready to explore CNC milling services with you and suggest effective solution for CNC machining parts, regardless of their complexity.

We thrive on overcoming all challenges! Send us your enquiry using the form below and we will get back to you with a precision CNC milled parts quotation!

To ensure we can provide you with an accurate and timely quotation,

please provide the following details:

1. Drawing: Do not forget to attach a detailed drawing(s) of the part.

2. Material Specification: Specify the material(s) required for the part.

3. Quantity Required: Indicate the quantity of parts required.

4. Additional Specification: Include any additional specifications such as ISO specification or customer-specific requirements.

5. Full Contact Details: Please provide your company’s full contact details.

6. Found Us Through: Let us know how you heard about APT Leicester. Your cooperation in providing this information will help us serve you better.

Thank you!

“We came to APT because we wanted high quality items to compete within the worldwide market. They were able to resolve any production issues of working with titanium. From the concept, to the product, to the market, APT were with us all the way.”